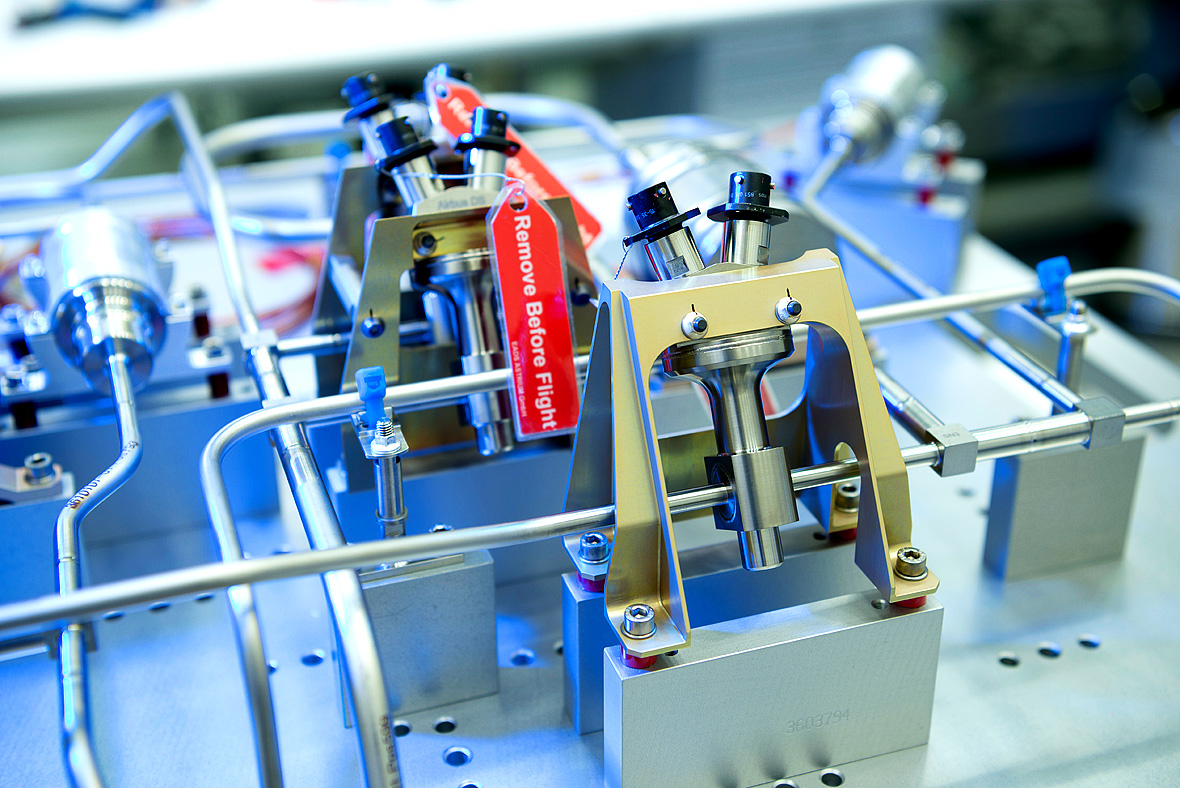

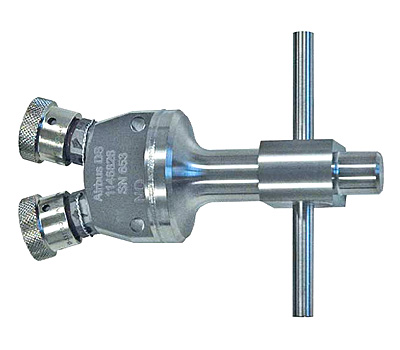

Pyrotechnic Valve

Our pyrotechnic valves are designed for spacecraft and launch vehicle propulsion systems where a reliable 'one shot' device is needed for the permanent opening or closing of a fluid circuit.

Due to its excellent leak tightness capability prior to and after firing in combination with its low mass and simplicity, the pyrovalve represents a state of the art solution to a range of propulsion system needs.

We offer a family of Normally Closed (NC) and Normally Open (NO) pyrotechnic valves with a variety of different interfaces to fulfil specific customer needs. The available product portfolio covers screwed as well as weldable tube interfaces (1/4” and 3/8”).

All valve types are provided with redundant ESA standard initiators (squibs) which provides the energy needed for actuation.

The main function of the pyrotechnic valve is to positively open or close a fluid circuit. Moreover, as part of a propulsion subsystem they must ensure a minimal pressure drop as well as perfect external and internal leaktigthness prior to and after actuation. The latter is achieved by an all welded titanium design in combination with a flexible titanium membrane, which pysically separates the combustion chamber from the hydraulic flow section. This membrane ensures a perfect pressure tightness between the pyrotechnic chambers and the fluid circuits before, during and after the actuation. The pyrotechnic valve provides a highly reliable, fast acting, zero liquid leakage compact design at low mass. Only a small pulse of electrical power is required for valve actuation.