Flow Control Valve

The following propellant control valves are readily available from our most popular range of monopropellant and bipropellant thrusters:

10 N Valve for Bipropellant Thrusters

The 10 N propellant flow control valve has been used on our 10 N bipropellant thrusters since 2005, providing orbital control of numerous major international satellites and spacecraft. The valve is designed for thruster applications demanding precision attitude, trajectory and orbit control of large satellites and deep space probes.

The 10 N flow control valve has been designed and qualified on valve level and thruster/valve combination.

The valve is of the dual coil, dual seat type and consists of two independent bipropellant units that are combined into one valve assembly comprising an upstream bi-stable latching valve and a downstream monostable solenoid valve.

The propellant part of the valve features an all welded titanium body with 40 micron inlet filter and Teflon seal / seat design.

The fuel and oxidiser flow is controlled simultaneously by one actuating device while the latching valve and the solenoid valve operate completely independent of each other. Moreover, the propellant and actuator parts of the valve are fully isolated from each other.

The valve is equipped with a micro switch for position indication. The first flight application of this all European 10 N valve was on Apstar 6 (Spacebus), launched in April 2005.

400 N Apogee Engine Flow Control Valve

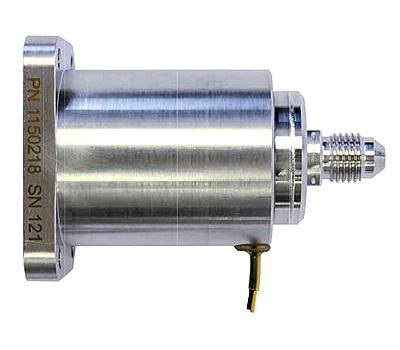

The 400N flow control valve is an electromagnetic controlled, normally closed valve with a non sliding fit suspended armature design with redundant electric coils.

The moving part, or magnetic plunger, is actuated by the magnetic force induced by the coil when supplied by direct current voltage. With no voltage applied, the magnetic plunger returns to the closed position due to two preloaded membrane springs. The spring preload compresses the PTFE poppet on the metallic seats to enable the correct seating pressure and leak tight seal.

After energizing the coil, the valve opens and propellant flow passes through an annular gap.

At the inlet of the valve a 40μ filter is located to protect the PTFE seat from any contamination.

More than 100 units have been produced, of which more than 80 have been used on the 400N apogee motor with total success..