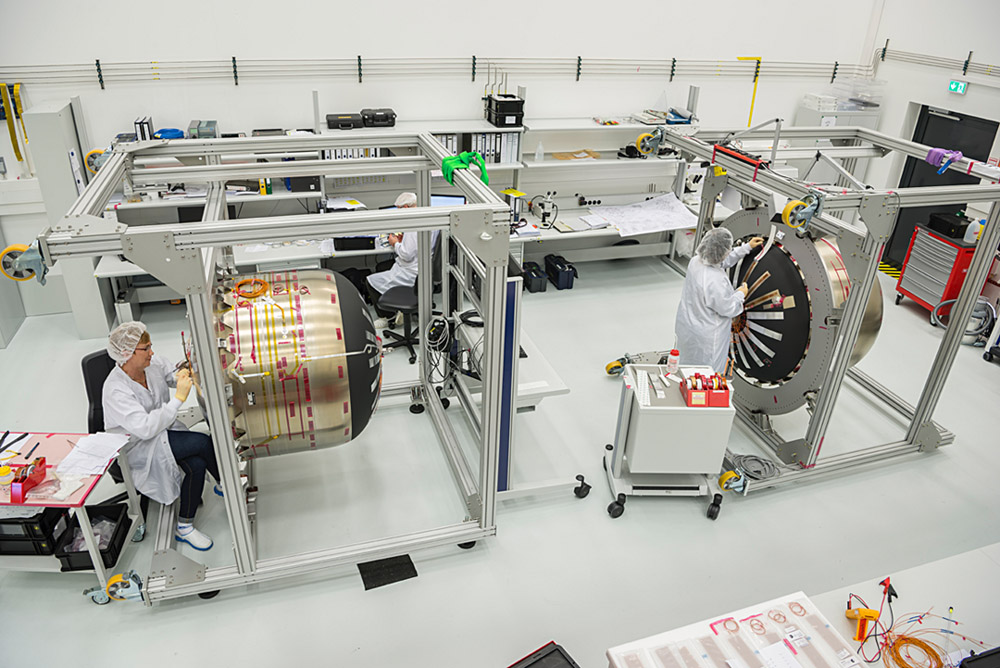

Propellant Tanks

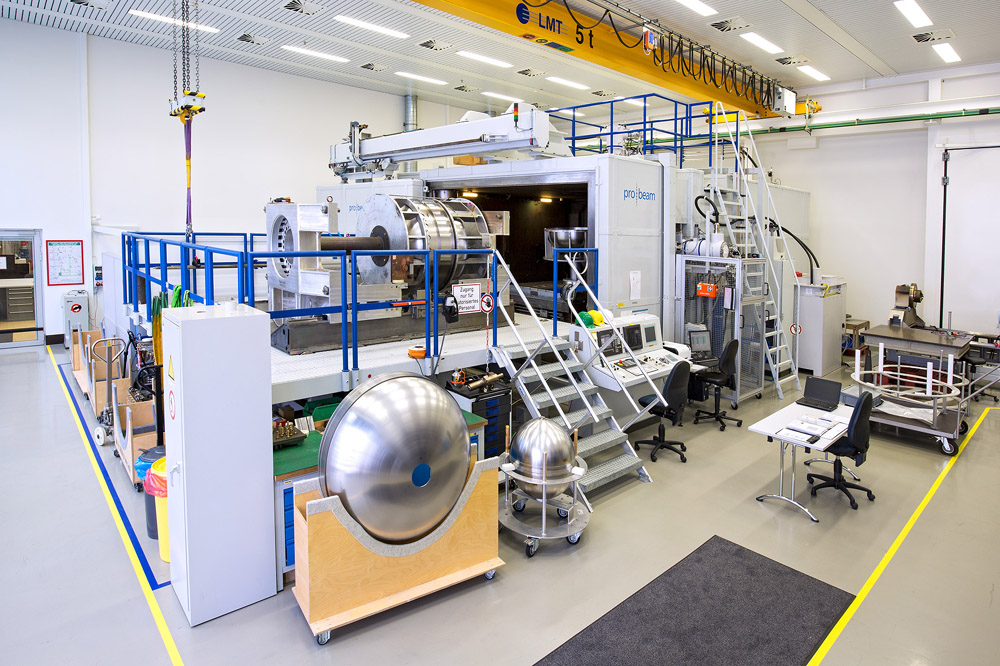

Manufacturing Overview

Our production centre dedicated to propellant tanks and related components is located in Bremen, north Germany.

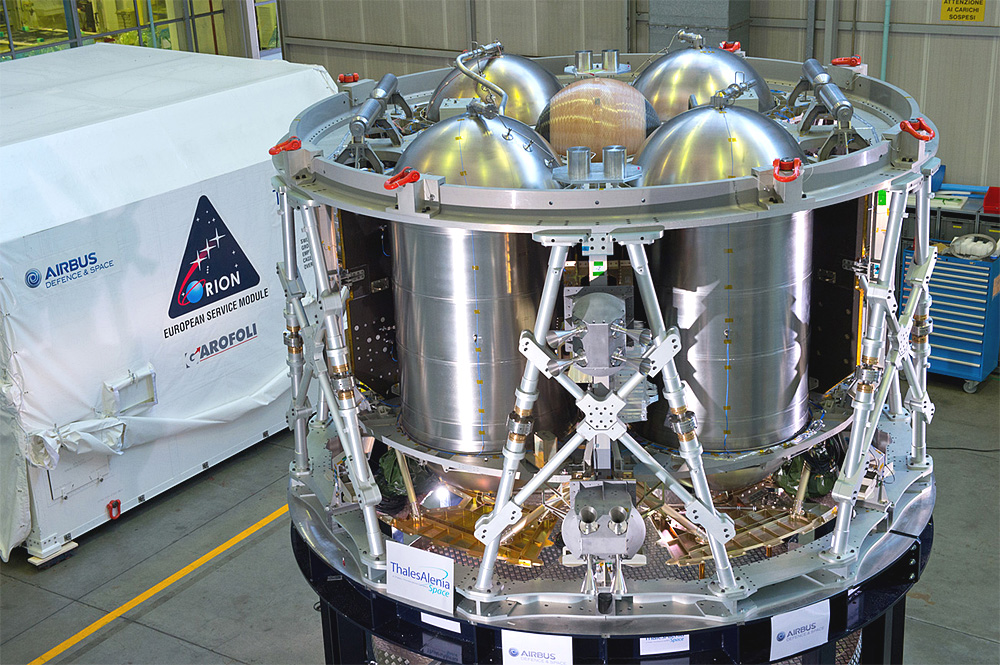

For over 40 years, the centre has been producing propellant tanks for scientific and commercial satellites, orbital platforms, space probes, interplanetary spacecraft, launch vehicle roll control systems and upper stage attitude and orbital control systems.

The Bremen facility is also well know for the integration of ESA's Automated Transfer Vehicle, booster integration of the Ariane launcher, upper stage integration of the bipropellant and cryogenic upper stages of Ariane 5, Rokot launch vehicle services, as well as integration of Europe's first manned spacecraft 'Spacelab'.

Today, the Bremen Production Centre is the European market leader for the design, manufacturing and supply of a diverse range of spacecraft propellant tanks, propellant management and acquisition devices and all tank related components and services. Propellant tank capacities range from 58 litres to 2100 litres. The space qualified tank portfolio is mainly focused on bipropellant tanks and monopropellant hydrazine tanks.

The different types of propellant tank produced at the Bremen facility includes surface tension propellant tanks, diaphragm / bladder tanks, propellant tanks for spin stabilised spacecraft and high pressure tanks.

Tank geometry may be adapted according to the required propellant mass and volume available for accommodation. Typical tank geometries are spherical and cylindrical with either hemispherical or Cassini shaped domes.