Fill, Drain & Vent Valves for Spacecraft Propulsion Systems

For propellants, pressurants and high pressure gases. Also ground half couplings.

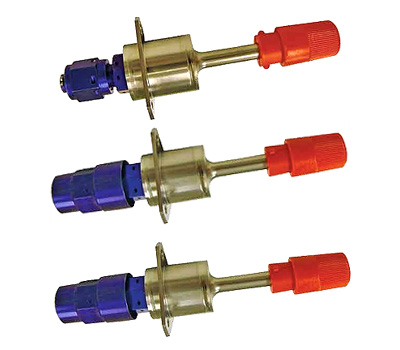

Fill and Drain / Vent valves

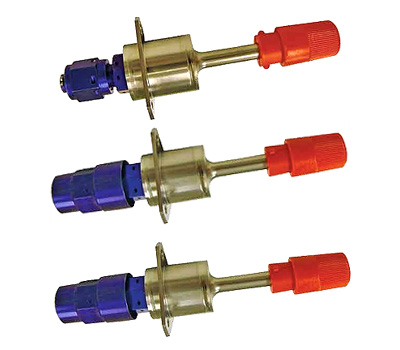

Range of FDV Valves

Our wide range of Fill and Drain / Vent valves (FDV) are typically used for the loading and venting functions of all kinds of

propellants, pressurants and propellant vapours.

All valves in the range are space qualified and fulfill the requirements for either two or three mechanical inhibits against

leakage . The valves can also be used for test port functions.

Valve Types

Six different valves types are available, each providing a different interface to prevent misconnection at spacecraft level.

These types differ mainly in thread size and orientation.

Propellant loading and venting valves are designed to provide three independent inhibits, while gas type or test port valves

provide 2 independent inhibits.

Propellant and test port FDV's provide excellent compatibility with storable propellants such as MMH, Hydrazine, MON- 1 as well

as MON-3.

Special high pressure gas type FDV's are available for operation with Helium (He) and Xenon (Xe). In general all types are

compatible with standard test agents (IPA / HFE 7100 / deionized water) and gases (He, N2).

Design Features

The following design attributes and features are common to all six types of FDV :

- All piece parts of the valve are machined from titanium alloy (Ti6Al4V) leading to a light weight unit with 0.25

inch/ 6.4mm outlet diameter tube stub which forms a weldable connection to the titanium tubing of the subsystem

- The interface to the subsystem structure is provided by a triangular flange with triple-screw attachment (thread

size M4)

- An all welded housing containing a spring supported guided valve poppet equipped with the primary seal. This

ensures that the valve is kept closed in non actuated conditions.

- In flight configuration the valve poppet sealing will be additionally protected and sealed by mounting a cap,

thus providing a metal-to-metal seal (secondary seal).

- Low pressure drop even at high mass flows ensured by design. The flow area is at least as large as the connected

tubing

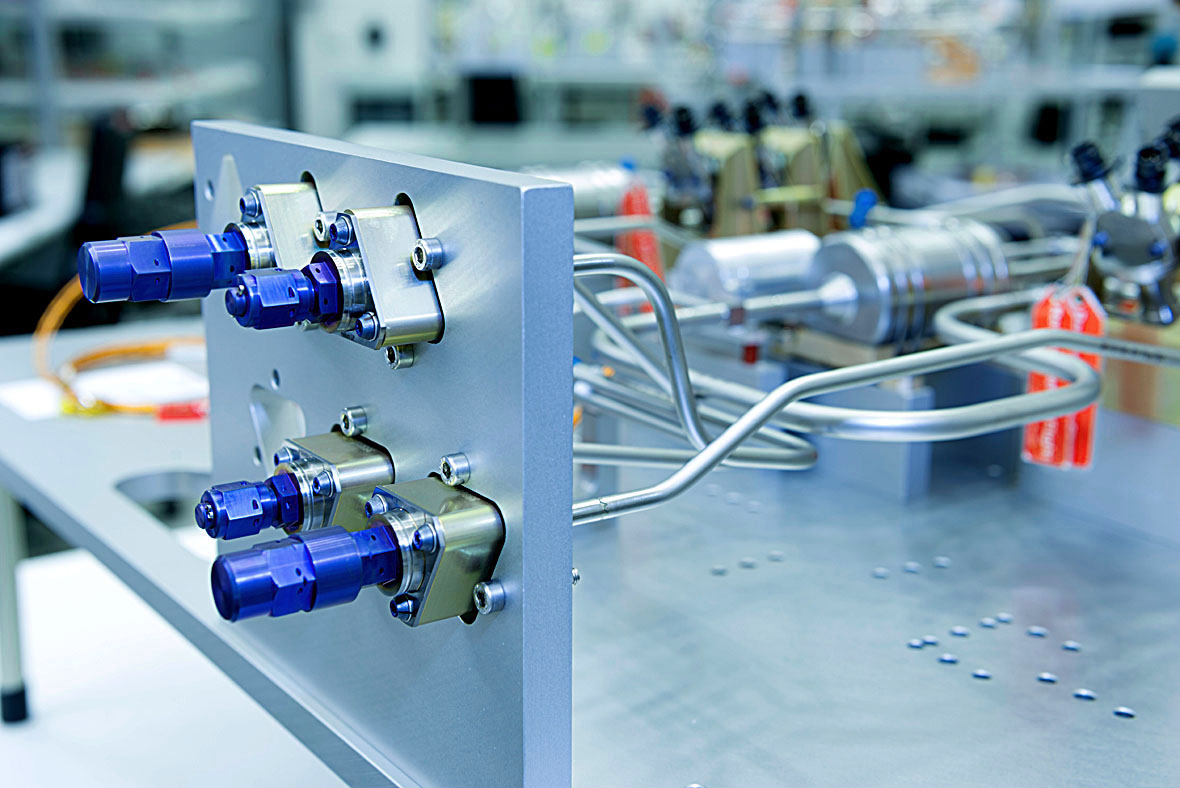

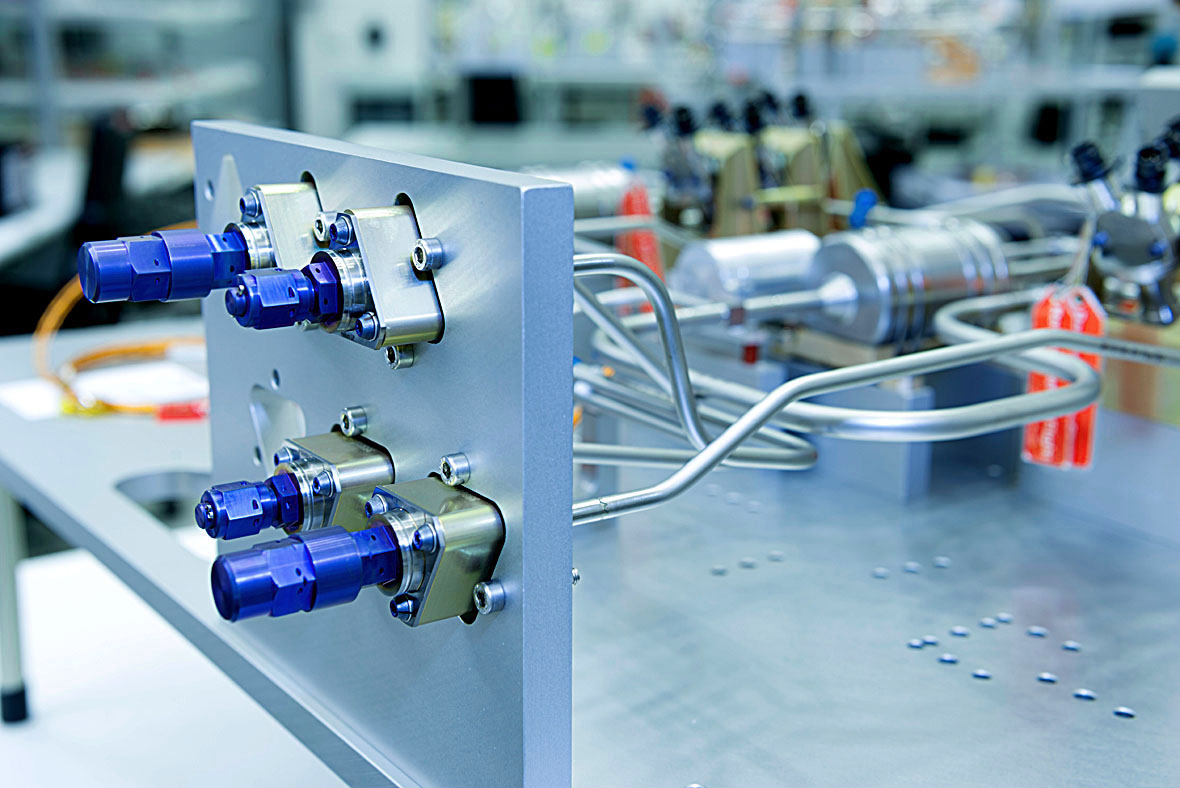

Ground Half Coupling

Ground Half Coupling

For servicing, a dedicated Ground Half Coupling (GHC) is required. For each FDV type there is a respective GHC permitting only

mating of the correct type. By this means a safe and easy to handle, leak-tight connection between the propulsion system and the

ground support equeipmnt is guaranteed.

Each GHC provides a robust specific opening / closing mechanism to safely operate the FDV. No specific tooling is required.

Main Features

- Actuation of FDV is made by manually operated pin.

- No generation of particles during opening and closing of the valve poppet.

- Easy monitoring of valve status (red safety clamp can be inserted in the closed position of the valve).

- Ground half coupling with bypass available for safe handling of toxic media.

- High compatibility with media due to the materials selected.

- Low pressure drop across the valve.

Integrated fill and drain valves

FDV Valve Characteristics

The characteristics of each off-the-shelf fill, drain and vent valve is shown below:

Operating Media

Monomethyl Hydrazine (MMH)

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02mm

5.58 + 0.11 mm

Adapter Thread

9/16" - 18 UNJF - 3A - RH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Monomethyl Hydrazine (MMH)

Total Length

112.5 ± 1 mm

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02mm

5.58 + 0.11 mm

Adapter Thread

7/16" - 20 UNJF - 3A - RH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Nitrogen Tetroxide (MON)

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02mm

5.58 + 0.11 mm

Adapter Thread

9/16" - 18 UNJF - 3A - LH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Nitrogen Tetroxide (MON)

Total Length

112.5 ± 1 mm

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02mm

5.58 + 0.11 mm

Adapter Thread

7/16" - 20 UNJF - 3A - LH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Helium (High Pressure)

Total Length

112.5 ± 1 mm

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02 mm

4.9 + 0.1 mm

Adapter Thread

M 12 x 1.5 - RH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Xenon (High Pressure)

Standard Tube Dimensions

- outer diameter

- inner diameter

6.4 ± 0.02 mm

4,9 + 0.1 mm

Adapter Thread

M 14 x 1.5 - RH. Requires

corresponding ground half coupling

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/sec GHe

< 2.8x10-4 scc/sec GHe

Operating Media

Various fluids

(Propellants and Pressurants)

Standard Tube Dimensions

- outer diameter

- inner diameter

- inner diameter (at weld i/f)

6.4 ± 0.02mm

4.9 + 0.01mm

5.58 ± 0.02mm

Adapter Thread

Fuel Loading 9/16" - 18 UNJF - 3A - RH.

Fuel Venting 7/16" - 20 UNJF - 3A - RH.

Ox Loading 9/16" - 18 UNJF - 3A - LH.

Ox Venting 7/16" - 20 UNJF - 3A - LH.

Note: All of the above threads require

corresponding ground half couplings

Life

- Operational Life

- Storage Life

About 16 years

Up to 5 years in a protected environment

Open/Close Cycles

40 Cycles

Standard Operating Temp.

243 to 353 K

MEOP

- Fuel / Ox Loading / Venting

Up to 33 bar

Leakage

- external Leakage

- internal Leakage

< 1x10-6 scc/s GHe

< 2.8x10-4 scc/s GHe

Sinusoidal Vibration

Up to 20 g

Random Vibration

Up to 5 g²/Hz (56.3g RMS)

Pyrotechnic Shock

Up to 3250 g

Heritage

Since their original qualification in 1983, thousands of fill, drain and vent valves have been produced and delivered for a

variety of spacecraft programmes including Eutelsat W3A, Amazonas, Inmarsat 4 F1, Anik F3, Skynet 5A, Skynet 5B, Amos 2, Astar, Star

1, Galaxy 17, Hispasat, MSG-4, Microsats, Herschel Planck, Pleiades, Spacebus, Eurostar communication satellites, Mars Express, Venus

Express and ESA's Automated Transfer Vehicle.

|

Fluidic Equipment

(PDF Brochure)

|

Fluidic Equipment Brochure (pdf)

This brochure is available to

view online from where it may be

downloaded.

Get the latest version of the free Adobe Acrobat Reader

If you require the printed version of this brochure, or more detailed information about this product please

contact us.

See the complete list of our space propulsion brochures

available for download.