200N Bipropellant Thruster

200N Thruster Background

The 200N bipropellant thruster was developed and qualified by Snecma (groupe Safran), for applications such as

attitude control, orbital manoeuvring and braking of ESA‘s Automated Transfer Vehicle (ATV).

ArianeGroup acquired the license to manufacture the thruster for ESA programme's and to modify the design in accordance

with programme needs. The transfer of both production and product design authority was accomplished at the end of

2009.

The ATV programme has served the International Space Station with the most complex space vehicle ever developed in

Europe, having achieved five launches in six years following its 2008 debut. The end of the fifth ATV mission

'George Lemaitre' in February 2015 marked the end of the ATV programme.

Using a 220N thrust level, the thruster has been

selected for the reaction control system of the NASA / ESA Orion

European Service Module. 24 of these manoeuvring thrusters are

used in 6 pods of four.

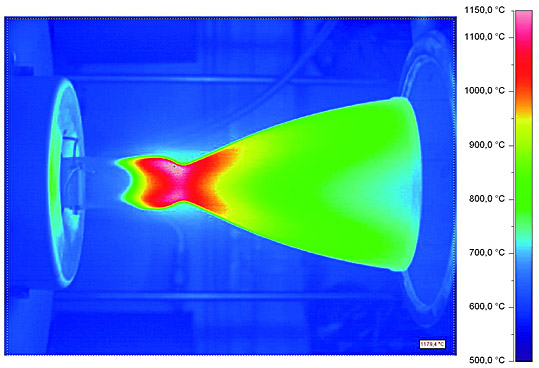

The engine is designed to be capable of both steady-state and pulse mode operation throughout very broad regimes

of inlet conditions whilst exhibiting outstanding thermal and combustion stability even at extreme conditions.

To meet the specific Fault Detection, Isolation and Recovery (FDIR) needs of man rated missions, the thruster is

equipped with flight sensors for continuously monitoring e.g. in-flight leak detection, chamber temperature and

combustion pressure.

The 200N thruster was designed and developed in accordance with the special ATV requirements, and exhibits the

following characteristics:

200N Thruster Operating Box

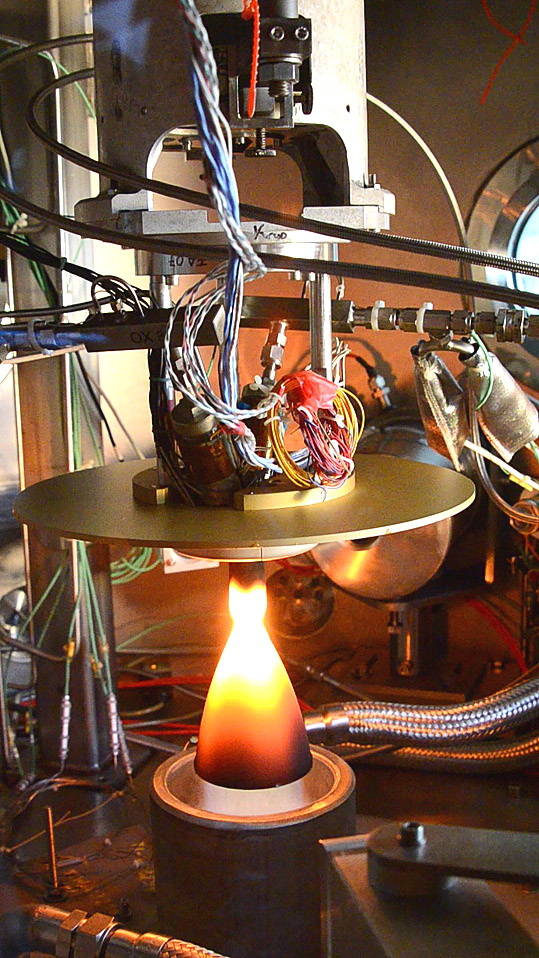

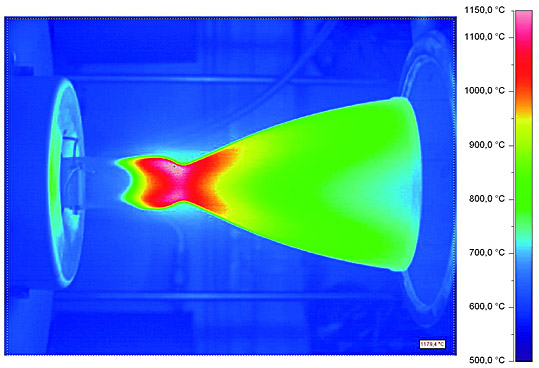

Temperature profile of 200N thruster taken with infrared camera

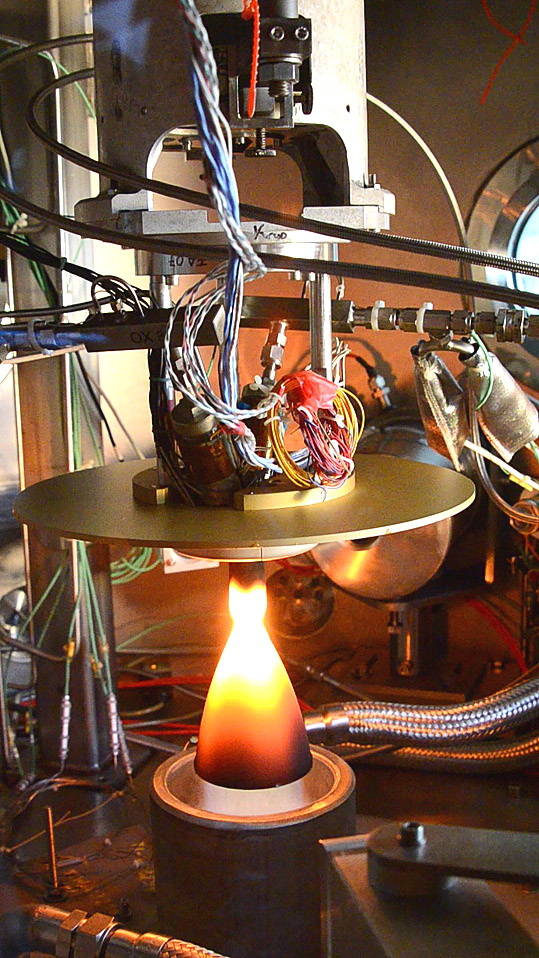

200N thruster firing test in high altitude chamber

Production of the 200N bipropellant thruster has been entrusted to the Lampoldshausen team to provide for the

special man rated requirements of the Automated Transfer Vehicle (ATV). Here, clusters of 200N thrusters were used

for attitude control and braking manoeuvres of the ATV during logistics resupply to the International Space Station

(ISS) and subsequent waste removal from the ISS. The 200N thrusters

are also used to assist orbit raising of the ISS, as well as providing redundancy in the event of a main engine failure

The thruster clusters deliver both steady state thrust and impulse bit and can also be used as back-up in the

event of main engine failure.

Safety and redundancy are major design drivers and each thruster is equipped to measure and detect malfunctions

and problems by continuously measuring chamber temperature and combustion pressure.

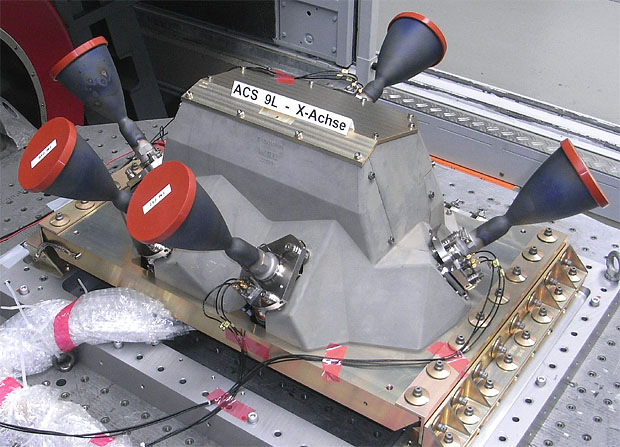

The Lampoldshausen team were also responsible for the production, integration and acceptance testing of the:

Automated Transfer Vehicle

220 N thruster clusters shown fwd and aft (red)

About the Automated Transfer Vehicle

On 9 March 2008, Europe's first Automated Transfer Vehicle (ATV), was launched by an ES ATV version of

Ariane 5. Its mission, to deliver its 45 m³ pressurised module containing up to 7.2 tonnes of equipment, fuel,

food, water and air to the crew of the International Space Station (ISS). This, the maiden flight of ATV was named

'Jules Verne'.

About 1,500 people in different European countries worked on this €900-million ESA programme.

As its name implies, the ATV was a truly automated vehicle. It could navigate and safely dock to the space

station and accomplish its mission without any human intervention whatsoever. The ATV was therefore the first fully

automatic resupply spacecraft of its kind. Such autonomy, together with its fault tolerance requirements, imposed

about one million lines of software code for the various onboard computers.

The ATV's were launched on an ES ATV version of Ariane 5, which placed the spaceship into a 260 km circular low

Earth orbit inclined to 51.6°. From this orbit, the ATV used its own propulsion system to automatically

navigate to, and dock with, the Space Station.

ATV Propulsion System

The ATV propulsion system is contained in the unpressurised Service Module, located aft of the habitable

Pressurised Module. The Service Module also contains electrical power, computers, communications and avionics.

The bipropellant propulsion system is pressure fed with the propellant combination monomethyl hydrazine fuel and

nitrogen tetroxide oxidiser. The main elements of the ATV propulsion being:

- 4 x 490N main navigation engines.

- 28 x 200N attitude control and braking thrusters.

- 8 titanium propellant tanks of 7 tonnes capacity.

- 2 high pressure carbon fibre-wound helium pressurant vessels.

The propulsion system is designed to perform:

- Navigation to the Space Station, after separation from Ariane 5.

- Automatic manoeuvres for rendezvous and docking to the ISS.

- While docked, the ATV will perform ISS attitude control, debris avoidance manoeuvres and

raising of the 417 tonne station's orbit to overcome the effects of atmospheric drag.

- After 6 months - de-docking and automatic departure manoeuvres.

- Navigation to the orbital deorbitation point.

- Retroburn and de-orbitation manoeuvres.

From the 7 tonnes of available propellant, approximately 2.3 tonnes is available for free flight manoeuvres and

approximately 4.7 tonnes is available for manoeuvring the space station at intervals of 10 to 45 days.

In the event of a thruster, or main engine failure, redundant branches and control electronics are used to

switch propulsive functions to fulfil operational objectives and safety requirements.

The scale of ATV, together with the complexity of propulsive

manoeuvres and proximity to man, results in a propulsion

subsystem that is one of the largest and most sophisticated ever

built. In fact, the internal volume of the complete ATV is

sufficient to accommodate a double-decker London bus.

More information:

ATV video

|

Bipropellant Thrusters

(PDF Brochure)

|

Bipropellant Thruster Brochure (pdf)

This brochure is available to

view

online from where it may be downloaded.

Get the latest version of the free Adobe Acrobat

Reader

If you require the printed version of this brochure, or more detailed information about this product

please contact us.

See the complete list of our space

propulsion brochures available for download.